Dongguan Zhiyuan Baili Automatic Equipment and Technology Co., Ltd.

Dongguan Zhiyuan Baili Automatic Equipment and Technology Co., Ltd.

The system has stable performance and can operate for 24h every day. The key parts are of imported brand or famous domestic brand. The machine performance is improved, and it also guarantees that the machine cannot have failure after high-speed run for long time.

1、Entirely-new air shower and dust removal system: 360 degrees without dead space, high-efficiency, energy-saving and other characteristics.

2、Support automatic stacking.

3、Substitute the traditional dust removal mode, improve the production efficiency. Reduce the packing labor force by more than half.

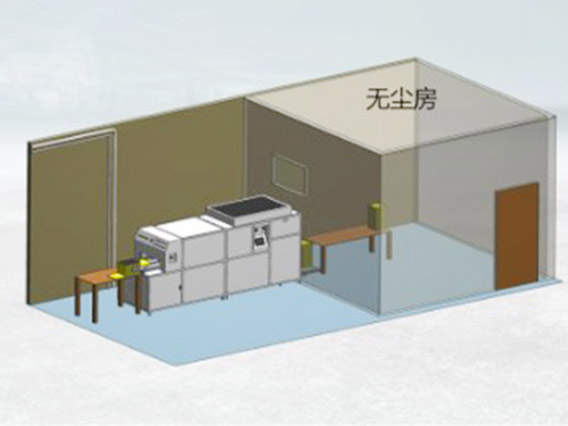

The system is connected to the packing room for supporting use. The cleaned products can directly flow into the dust-free room, and the required dust-free environment is reduced by great degree.

Traditional:dust-control---mode:—From,raw material—warehouse—production—package.

Main products:

1、Main functions: Neutralizing product surface electrostatic value, cleaning the product surface dust, hards and particles. While cleaning, effectively suctioning the dust particles.

2、Dust removal mode: Non-contact type cleaning, air showering type cleaning, electrostatic dust removal.

3、Applicable product:Trays for electronic, medical apparatus and food.

4、For the equipment electric control, PLC programming is used to control the front and rear screen-touching central console, machine console operation is more convenient and faster. The equipment circuit is easily repaired, and the failure rate is very low.

5、The cleaning pressure can be adjusted. Automatic counting is conducted after product cleaning. If the set quantity is completed, the products will be automatically sent to the packing area.

6、Work place: Ordinary production workshop+package dust-free room.

7、Inside the equipment, the high-efficiency dust filtration system is built in: The traditional pipe dust exhaust mode is substituted and the environmental protection requirements are met.

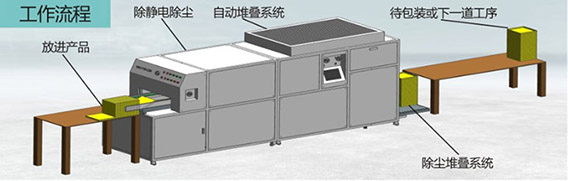

Operation flow:Material feeding area → Electrostatic air shower and dust removal area → High-pressure air shower → Secondary air shower → Automatic stacking → Pushing to the platform→ Removing electrostatic→ High-pressure air show→ Automatic stacking→ Push out and complete